Large-Format Robotic Additive Manufacturing

Project Overview

Goal: Expand the capabilities of large-format material extrusion through robotic deposition (see Robotic Material Extrusion) and utilization of the other unique capabilities of robotic manipulators (e.g., ease of tool changes for integrating a secondary tool).

Description: Large-format Additive Manufacturing (AM) is typically quantified by any system with a build volume in excess of 1 m3. Specific to material extrusion (ME), there are only three commercial large-format systems currently produced: The ORNL/CI Inc. BAAM, Thermwood LSAM, and Ingersoll Machine Tools MasterPrint, with the primary application being printing large tooling fixtures and fiber layups. All of these systems use 3 degree of freedom (DoF) gantry motion stages, which are limited to vertical (perpendicular to the ground) deposition. By using a robotic arm in place of the traditional gantry, this limitation is removed, enabling multi-axis deposition, which has been shown to increase part strength, produce a finer surface finish, and allow for embedding of components (e.g., RF antenna) on a curved surface. Furthermore, existing large-format ME systems are unable to print removable support material due to the layer widths of up to 25 mm, limiting the features that can be printed. With a robotic arm, the extruder can easily be changed mid-print to use a secondary extruder to deposit a water-soluble support material, eliminating this limitation.

Project History: The first iteration of the LFRAM system was completed in the spring of 2019 in a collaboration between the DREAMS lab and the Center for Design Research (CDR). This system featured a single-screw extruder capable of extrusion up to 20 lb/hr. This system was later updated in Fall 2019 to use a large extruder capable of extrusion up to 150 lb/hr, rivaling many of the commercial systems. Since that time, the system has been continuously updated and modified to enable more complex operations such as multi-axis deposition and tool changes.

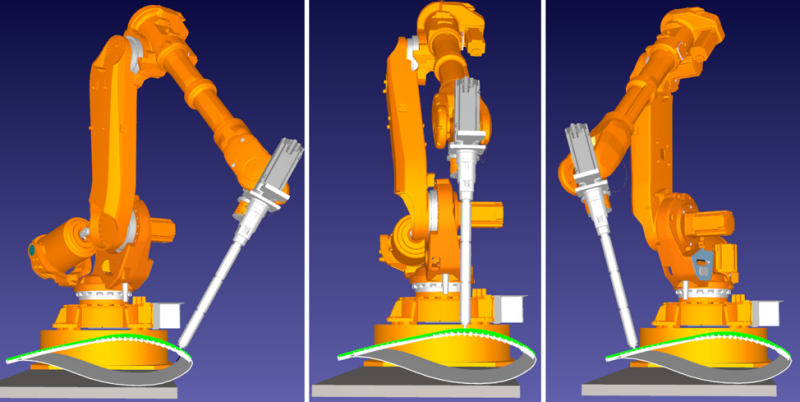

Research Projects: The surface finish of parts made via large-format AM are inherently rough due to the layer heights of 12+ mm. To remedy this, an algorithm was developed to enable 5 DoF conformal printing. Traditional AM processes work by stacking ‘slices’ of a part in the Z direction (vertical) that were laid in the X-Y plane. Conversely, conformal printing uses a curved layer that drapes over the surface of the part being manufactured. Additionally, in conformal printing, the extruder deposits the print material at an orientation normal to the surface rather than normal to the ground. The result of this is a finer surface finish with an absence of the stair-stepping effect seen on parts manufactured by traditional AM processes.

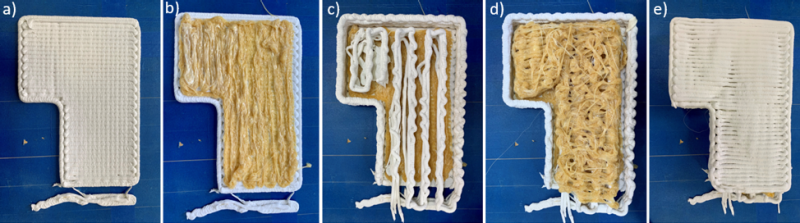

As discussed above, traditional large-format ME systems are unable to print support material that can be removed without post-process machining due to the layer widths of up to 25 mm. Additionally, while smaller-scale ME systems can change materials quickly due to being filament-based, the single-screw, pellet-fed extruders used in large-format ME require a full barrel purge to change materials which is both time-intensive and costly. To remedy this, a process of conducting tool changes mid-print to deposit a secondary material was developed. The process is shown below and consists of tool changes to print a water-soluble support interface layer and a novel method of breaking the support material into smaller chunks to enable removal.

LFRAM Videos

This video shows a time lapse of a 3D-printed chair that was a collaboration between the DREAMS Lab and the Center for Design Research. This print took about 3 hours and stands roughly 18 inches tall.

Ben Woods of the DREAMS Lab printed a DU91W250 airfoil using the large-format robotic additive manufacturing machine. It is 4-feet tall, weighs about 80 pounds, was printed in under four hours, and marks the largest object ever 3D printed at Virginia Tech.