Adhesion of Multi-Material Interfaces

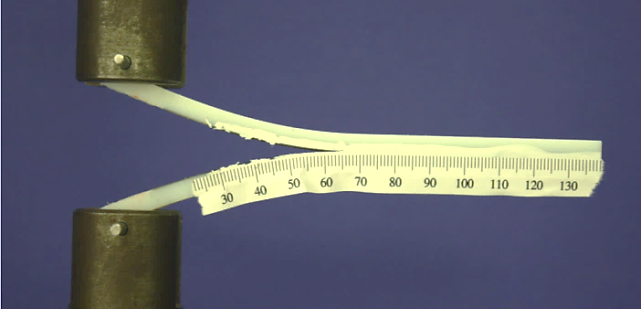

Multi-material AM allows for the fabrication of end-use products with enhanced, multi-functional capabilities. The applications for multi-material jetting are on the rise and include prosthetics via flexible hinges in a rigid structure, biologically-inspired robots, and embedded electronics. Accompanying the rapid advances of AM technologies are concerns to ensure efficient processing of robust and durable structures and components. Just as interactions at interfaces have been of interest in the area of adhesive bonding, similar issues need to be addressed for printed composite materials. Specimens were designed with a flexible polymer sandwiched between two stiffer strips of a rigid polymer. Several test methods based on the double cantilever beam specimen were evaluated to characterize fracture resistance between the rigid and flexible jetted polymers. Multiple orientations were tested and showed a clear direction dependence in fracture energy. Tailored design of multi-material interfaces has also been considered and evaluated to achieve desired fracture resistance and tunable mechanical properties.

Related Publications:

Vu, I., Bass, L., Williams, C., and Dillard, D., "Characterizing the effect of print orientation on interface integrity of multi-material jetting additive manufacturing". Additive Manufacturing, 2018. 22, 447-461.

Vu, I., Bass, L., Meisel, N., Orler, B., Williams, C., and Dillard, D., Characterization of multi-material interfaces in PolyJet additive manufacturing. In International Solid Freeform Fabrication Symposium. 2015. Austin.