Manufacturability Assessment in Additive Manufacturing using Voxels

Project Overview

Goal:

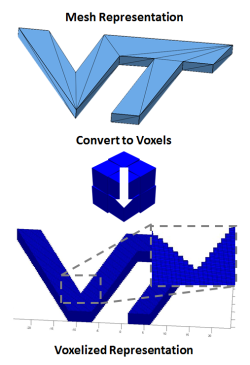

To develop a basic workbench for Additive Manufacturing which uses a voxelization approach to convert a triangular mesh into a grid of cubes which will allow an individual to perform manufacturability analysis of a given part.

Description:

This tool will provide a quick feedback on factors that govern manufacturability such as minimum feature size, volume of support material required, optimum orientation of the part, volume of material required and time taken to manufacture the part. This will be implemented in an undergraduate level course to help students visualize and make quick decisions regarding the manufacturability of their design.

Research Lead

Saish Tedia

Sponsors

This work was supported by NSF CMMI grant 1546985