Fiber Embedding and Actuation

Project Overview

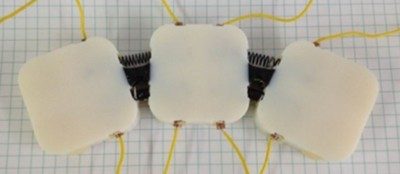

Additive manufacturing’s layer-by-layer fabrication approach allows the user to access the entire volume of the part throughout the build process. This allows for the embedding of functional components and actuators to enable the fabrication of complex systems in a single process. A process for the embedding of shape memory alloy (SMA) actuating wire within direct PolyJet 3D Printed parts has been developed in the DREAMS Lab. To complement this process, a series of “Design for Embedding” considerations have been identified and investigated for achieving successful and repeatable embedding results. These considerations include guide channel design, design of shape converters for irregularly shaped elements, and design of wire fixation points. The embedding process has been demonstrated with multiple case studies including a simple compliant joint specimen with a straight SMA wire and an antagonistic joint design with spring-shaped SMAs. Process characterization is also being performed, which focuses on the potential for surface defects in the final specimens, as well as basic quantitative and qualitative evidence regarding performance of the final embedded actuators. This work is sponsored by the Air Force Research Lab.

Research Lead

Nick Meisel