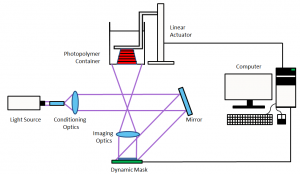

Constrained Surface Projection Stereolithography

Process Type: Mask Projection Microstereolithography

Features and Specifications:

- Cross sectional build area of 38.1 mm x 57.15 mm

- Minimum feature size of 300 um

- Optimal layer thickness of 200 um

- Vertical Build Rate of 75mm per hour

- Materials of Objet Veroclear Fullcure 810

Description and Benefits:

This machine uses a broad spectrum light source to cure photopolymers by projecting 2D images using a Digital Micromirror Device. This machine was developed by students in the lab; and unlike commercially available machines, the hardware and operating software of this process can be completely customized for more specialized applications. The constrained surface design cures photopolymer layers between a glass plate and the previous layers. The newest layer is peeled from the glass, which is coated in oxygen inhibiting PTFE Teflon to reduce adhesion. This allows for an economically advantageous processes that requires less photopolymer and has a vertical build rate greater than other projection stereolithography systems. The peeling process performed in the constrained surface technique, however, limits the achievable minimum feature size.