Orientation and Aging Effects in Multi-Material Jetting

Project Overview

Goal:

Understanding how material jetting process parameters affect material properties can inform design and print orientation when manufacturing end-use components. This study explores the robustness of material properties in material jetted components to variations in processing environment and build orientation.

Design/Methodology/Approach:

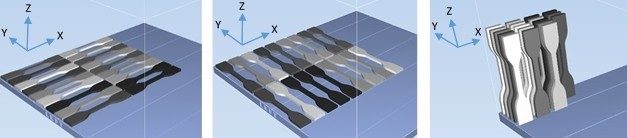

The authors characterized the properties of six different material gradients produced from preset “digital material” mixes of polypropylene-like (VeroWhitePlus) and elastomer-like (TangoBlackPlus) materials. Tensile stress, modulus of elasticity, and elongation at break were analyzed for each material printed at three different build orientations. In a separate 10-week study, the authors investigated the effects of aging in different lighting conditions on material properties.

Findings:

Specimens fabricated with their longest dimension along the direction of the print head travel (X-axis) tended to have the largest tensile strength, but trends in elastic modulus and elongation at break varied between the rigid and flexible photopolymers. The aging study showed that the ultimate tensile stress of VeroWhitePlus parts increased and the elongation decreased over time. Material properties were not significantly altered by lighting conditions.

The study provides the first known description of orientation effects on the mechanical behavior of photopolymers containing varied concentrations of elastomeric (TangoBlackPlus) material. The aging study presents the first findings on how time effects parts made via material jetting.

Publication

Bass, L. B., Meisel, N. A., and Williams, C. B. “Exploring Variability of Orientation and Aging Effects in Material Properties of Multi-Material Jetting Parts.” Proceedings of the 26th Annual International Solid Freeform Fabrication Symposium, Austin, TX. 2015. (Best Paper Award)