Vat Photopolymerization Processing of Alumina

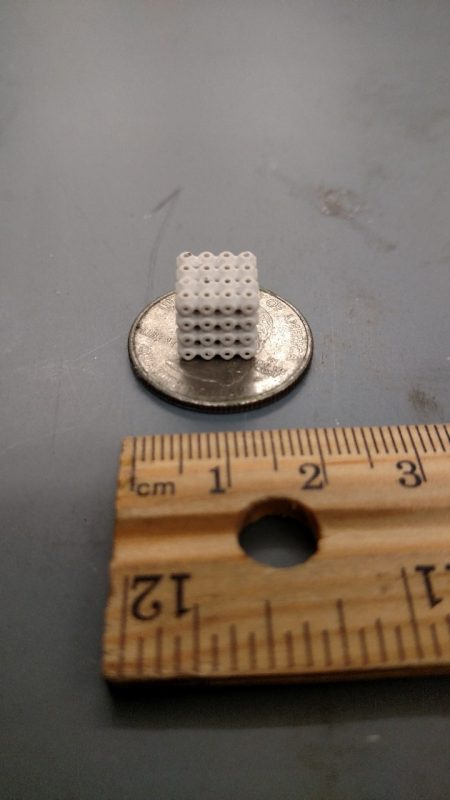

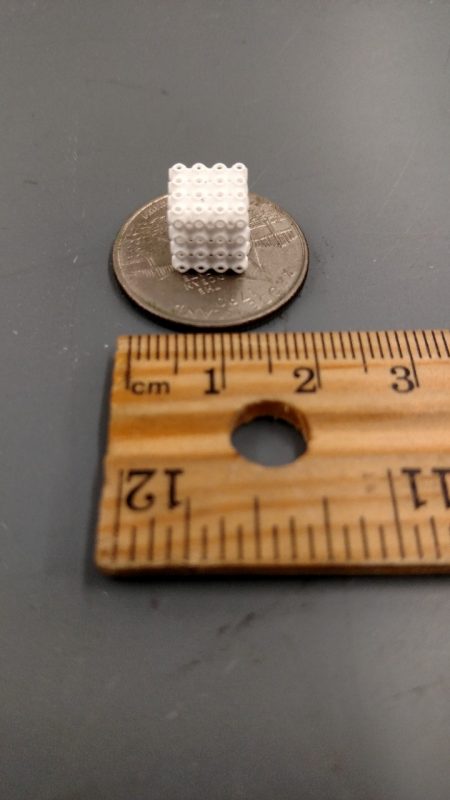

Alumina is a high-temperature high-strength ceramic with properties desirable for many applications. We have had initial success printing alumina at resin loading concentrations from 40%-60% by weight. The powder is loaded into the photocurable resin and cured layer by layer by the printer to its desired shape using UV light. After printing, the parts are then cleaned and sintered at a high temperature (1300-1550 ºC). The photocurable resin is burned away and the ceramic powder aligns and sinters, forming a dense ceramic structure.

Alumina has many applications for mechanical parts, including high-temperature parts that are also tolerant to harsh chemical solvents. Alumina is also a very high-performance low loss dielectric for use in high-speed electromagnetic systems. Potential applications for these systems include its use a low loss dielectric for resonators, antennas, filters, and waveguide structures. Future work will include detailed dielectric measurements and the attempt at creating composite ceramic and metal structures.

Research Leads

Don Aduba Jr., Rich Dumene