Metal Plating Complex Polymer Geometries

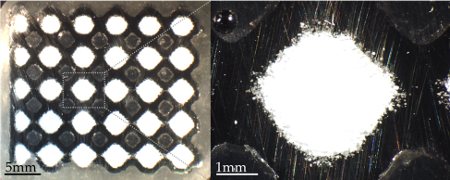

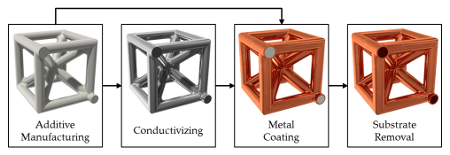

Plating metal onto polymer parts offers many potential benefits, usually to provide properties typically associated with metals like reflectivity, electrical and heat conductivity, abrasion resistance, decorative effects, etc. While this is common for traditionally manufactured geometries, like many car parts, there is limited research involving metal plating on additively manufactured geometries. Such research is typically focused on improving mechanical properties or for decorative effects. This project investigates an approach similar to electroforming, where a secondary burnout phase is used to remove the initial polymer part, resulting in a hollow metal geometry.

This research involves the design and improvement of a hybrid manufacturing process to produce such structures, taking advantage of the complexity allowed with additive manufacturing to produce complex, hollow, metal geometries for new applications, like producing heat exchangers and lightweight structures.

Research Lead

Drew Snelling