Improving the Lifespan of Nylon-12 Powder for Powder Bed Fusion

Project Overview

Goal:

To increase the re-processability of Nylon-12 powder used in powder bed fusion and to improve the density of sintered parts.

Description

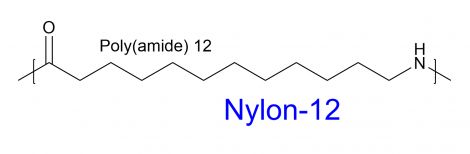

Although powder bed fusion has been around for 30 years, the understanding of what makes polymeric materials suitable for the technology does not yet match our knowledge of the machine process. There is significant research dedicated to studying how different machine settings influence the material properties of the printed parts, specifically with the commercially available sintering powders based on poly(amide)-12 (Nylon 12). Many of these studies report a decline in the mechanical properties of manufactured parts following repeated heating of the un-sintered powder particles. Increasing part density in powder bed fusion is another area with significant research opportunities . Increasing the part density will increase strength and make sintered parts more comparable to parts made using injection modeling. The purpose of this research project is to increase the density of sintered polymer parts and the re-processability of the heated, unsintered powder by modifying the chemical structure of commercially available materials. We hope to make a large impact on the quality of laser sintered polymeric parts through a modifications in the chemical structure. The knowledge gained through this study will help the ease and celerity of further research in developing novel materials for the powder bed fusion process.

Sponsors

Industrially Sponsored