Microstructural Analysis of Sintered Bioceramics Printed by Vat Photopolymerization

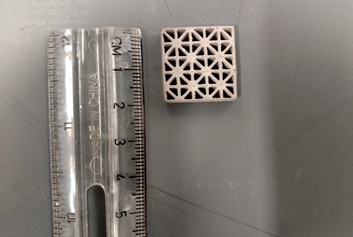

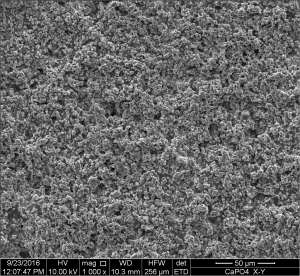

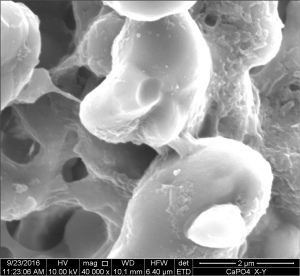

Ceramics are high-performance materials that are processed from crystalline powders into slurries that can be 3D printed using vat photopolymerization. They are sintered at temperatures commonly above 1000 degrees C to remove the photocurable binder while the ceramic grains orient and come together at a point of contact to form parts with densities near 90% based on our work. Ceramics inherently possess high strength but are brittle if cracks are present, causing mechanical failure. Fracture analysis of sintered 3D printed ceramics using Scanning Electron Microscopy provides information on defects down to a single micron that explains the cause of these failures either in the microstructure or within the bulk of the part. In the microstructure, the presence of grains and voids can indicate if there are internal stresses caused by the sintering process that leads to premature failure under applied loads. Therefore, sintering parameters such as the temperature, sintering rate and presence of gasses in the sintering oven need to be controlled to fit the type of ceramic. Also, the solid loading concentration of the ceramic particles can improve final sintering density which minimizes voids and potential defects. In future work, studies will be conducted on sintered ceramics printed by vat photopolymerization to predict mechanical strength based on the microstructure and sintering profile.

Photos: High-resolution images 1000X (left) and 40000X (right) of fractured Calcium Phosphate bars after sintering.

Research Lead

Donald Aduba Jr.

Sponsors

Industrially Sponsored