Material Jetting

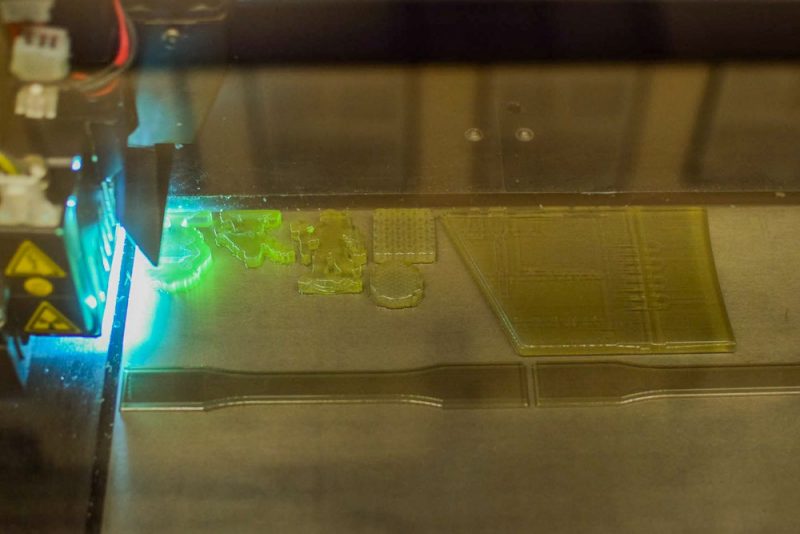

Material jetting is similar to inkjet document printing, but instead of jetting drops of ink onto paper, PolyJet 3D printers jet drops of liquid photopolymer onto the build tray. Multiple print heads jet material simultaneously to create each layer, and UV light is then used to cure the layers. These layers build up one at a time in an additive process to create a 3D model. Fully cured models can be handled and used immediately without additional post-curing. Along with the selected model materials, a gel-like support material facilitates successful printing of complicated geometries. Support material can be removed by hand or by a high-powered water jet station.

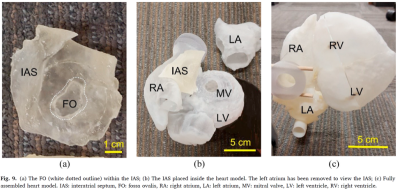

Material jetting was the first additive manufacturing technology that could combine different print materials within the same 3D printed model in the same print job. Additionally, the multi-material printing process is capable of constructing functional assemblies, which reduces the need for multiple builds.

For more information on the material jetting process, see:

- C. B. Williams and L. B. Bezek. "Material Jetting of Polymers" ASM Handbook Volume 24: Additive Manufacturing Processes, edited by D. Bourell, W. Frazier, H. Kuhn, and M. Seifi, ASM International, 2020.

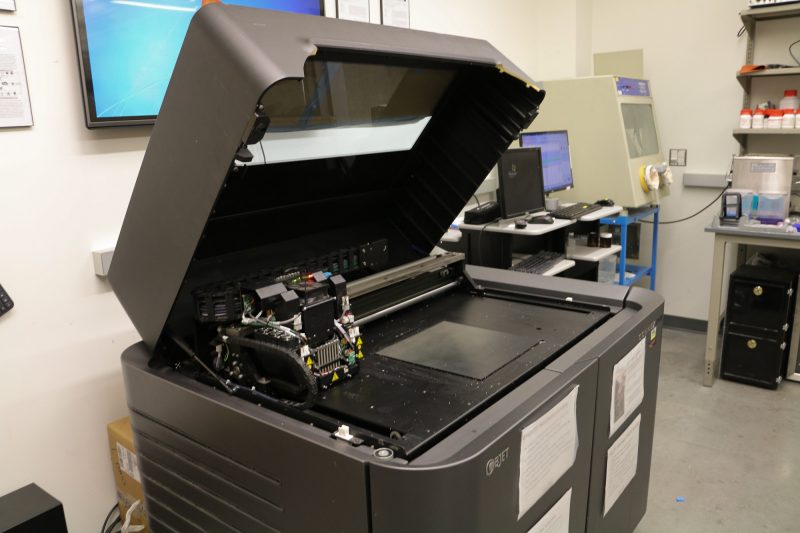

Stratasys Connex350 PolyJet Printer

Features and Specifications:

- X-Y resolution of 600×600 DPI (42 microns in each direction)

- Layer thickness of 16 microns or 30 microns

- Matte or glossy surface finish

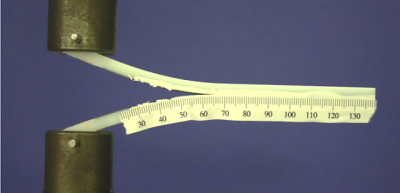

- Multiple-material printing (rigid and flexible materials, as well as gradient combinations)

- Build volume of 350x350x200 mm

Active Projects

-

General Item

-

General Item

Past Projects

-

General Item

-

General Item

-

General Item