Multi-axis Robotic Deposition

Large-Format Robotic Pellet-fed Material Extrusion

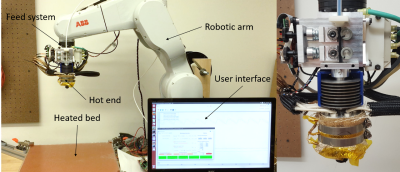

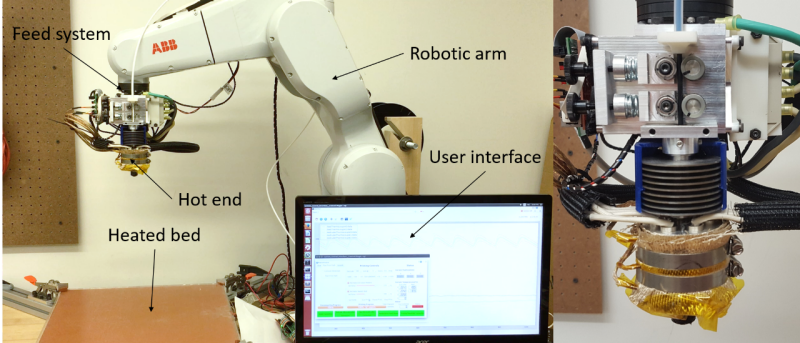

(ABB IRB 6640 130/3.2 + Model 30 Stragepresse)

The LFRAM (Large-format Robotic Additive Manufacturing) system is a custom material extrusion system built through a collaboration between the DREAMS Lab and the Center for Design Research (CDR). Unlike typical material extrusion systems, the LFRAM uses an industrial robotic arm to control movement and orientation of the extruder, and a single-screw, pellet-fed extruder as opposed to the conventional filament-fed extruder. It is the largest printer at Virginia Tech with a print volume of over 20 m3 and is capable of layer heights of 5-12 mm, layer widths of 7-25 mm, and extrusion rates of up to 150 lb/hr. Additionally, due to its robotic arm base, it is capable of conformal printing as well as other types of multi-axis deposition.

This video shows a time lapse of a 3D-printed chair that was a collaboration between the DREAMS Lab and the Center for Design Research. This print took about 3 hours and stands roughly 18 inches tall.

Ben Woods of the DREAMS Lab printed a DU91W250 airfoil using the large-format robotic additive manufacturing machine. It is 4-feet tall, weighs about 80 pounds, was printed in under four hours, and marks the largest object ever 3D printed at Virginia Tech.

Mid-scale Robotic Additive Manufacturing (ABB IRB 1200-7/0.7)

Active Projects

-

General Item

Past Projects

-

General Item