Direct Ink Write

Direct Ink Write (DIW) involves a controlled selective deposition of material according to a pattern. The material is usually patterned through a nozzle, whose movement is controlled and set-up to follow a specific pattern. This can be achieved through different ways such as extrusion of liquid ink, ejecting material-droplets onto a substrate or through aerosol jetting. DIW techniques are capable of single or multi-layer patterning of material onto flat as well as conformal surfaces. The process can achieve high-resolution in material-deposition. DIW enables development of embedded circuitry and rapid manufacturing of sensors. The advantage over conventional fabrication of electronics is in elimination of masking and etching steps.

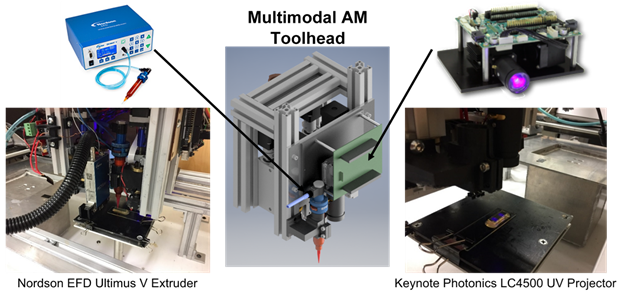

Recently, the lab has put a focus on the Ultraviolet-Assisted Direct Ink Write (UV-DIW) of novel photopolymers. In this process the ink is extruded via DIW and then cured and solidified with exposure to UV irradiation. The ability for DIW to process high viscosity inks has enabled the processing of novel high performance, high molecular weight photopolymers not processable by Vat Photopolymerization. This work has led to development and printing of all-aromatic polyimides and latex elastomer.

(Custom-built) UV-Assisted Direct Ink Write System (Nordson Ultimus V dispenser and HPx High-Pressure Dispensing Tool)

An extrusion based direct write process has been developed specifically to pattern conductive inks. A Nordson EFD Ultimus V high precision dispenser is used to extrude the conductive ink (DuPont 5201) and the translation of the nozzle is controlled, using an Arduino program which interprets the g-code. The system can be integrated with PolyJet process and hence deposit conductive ink into PolyJet structures or into the custom built Multi-Tool Additive Manufacturing System for UV-DIW printing.

(Custom-built) UV-Assisted Direct Ink Write System (Fisnar DC 100 High Precision Dispenser)

(Custom-built) UV-Assisted Co-Extrusion Direct Ink Write System (Viscotec eco-DUO450)

Active Projects

-

General Item

-

General Item

-

General Item

-

General Item

-

General Item