Polymer Powder Bed Fusion

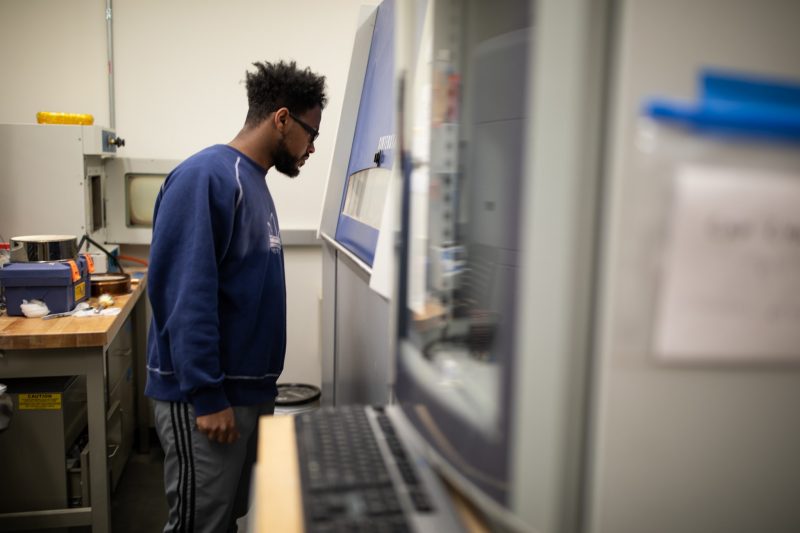

DTM Sinterstation 2500 Plus

This powder bed fusion AM system provides users full control over process parameters (laser power, scan speed, hatch spacing, oven temperature) and are therefore suitable for exploration of new materials and process conditions. It features a 100 W laser, 13 x 11 x 16.5 in build volume, and maximum chamber temperature of 220° C. |

Prodways ProMaker P2000 HT

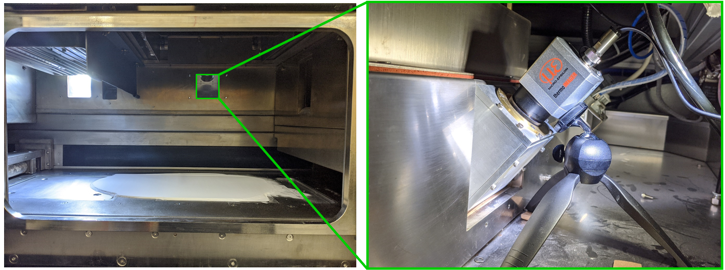

| This high-temperature laser sintering system is capable of a maximum chamber temperature of 220° C and features a 60 W laser and 250 x 250 x 320 mm build volume. This system requires a smaller amount of powder for printing, which helps explore novel materials. The DREAMS Lab has equipped this system with an IR camera, which can measure temperatures of the powder bed in-situ during printing. |

Selective laser sintering (SLS) is an Additive Manufacturing (AM) technique which uses lasers as its power source to sinter powdered material into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3D model of the part on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

- Strength: Since the laser is actually melting the powder together, the part is very strong.

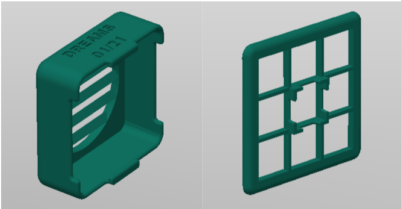

- Detailed Features:Very detailed features can be created because the laser point is very small.

- Powder Bed Provides Support Structure: Unlike non-powder-based processes, SLS uses the powder that surrounds the part to support over-hanging features instead of having to build and later remove support structure.

- Simple Post-Processing: When the part is made, the user merely retrieves it from the powder bed and brushes off any remaining powder.

- Recyclability: All leftover powder in the build chamber can be reused in the next build.

-(pps)-at-temperatures-significantly-below-melting-temperature/Picture1.png.transform/s-medium/image.png)