PBF Printing of N95 Filter Components for Carilion Clinic

Project Overview

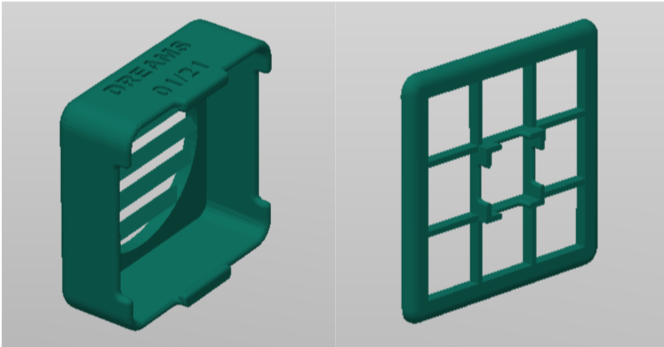

The DREAMS Lab has partnered with Carilion Clinic to print N95 mask components in response to the rise COVID-19. Through a couple iterations, the Clinic has settled on a design that will allow doctors, nurses, and other first responders, at their facility, the ability to reuse their respective N95 masks by replacing the filter housing component. There are two components displayed in Figure 1. These components work specifically with the 3M 6000 series respirators.

A respiratory filter is placed into the louvered filter housing component. The inner grid component is then nested in the housing component to constrain the filter from moving while in use. This assembly is then attached to the N95 masks using the clip features displayed in the Figure 1.

These components are being printed using powder bed fusion technology on the Prodways ProMaker P2000 HT and the selected material is Nylon-12. An industry standard of blending using a third of virgin, overflow, and cake powder is being implemented to be efficient with material consumption.