Non-Destructive Evaluation of Parts via Impedance-Based Monitoring

Project Overview

Goal:

To develop methods of non-destructive evaluation of parts fabricated through additive manufacturing using piezo-ceramics.

Description:

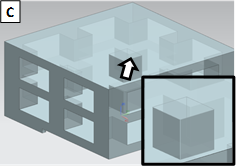

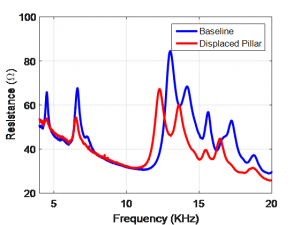

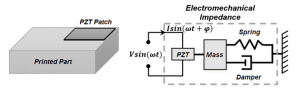

Piezo-ceramics have been used in structural health monitoring applications such as detecting damage to load bearing beams. In this project these techniques are expanded to parts fabricated using additive manufacturing techniques. By determining a baseline part signature defects or damage can be detected. This method is particularly of interest in additive manufacturing due to its ability to detect defects in hard to measure locations such as inside of complex geometries or voids that are completely enclosed inside the part. Piezo-ceramics offer a way to detect internal voids that is less expensive that CT scanning the current best method for detecting voids. These sensors can also remain with the parts during their life-cycle to allow for continued testing and monitoring. In this project piezo-ceramics are bonded to part geometries to form a mass-spring-damper system. The piezo is then run through a range of frequencies and the impedance is measured at each frequency. These measurements form a distinct signature for the part. Any change to the part will result in different system dynamics and will change the signature of the part. By monitoring this change in signature, part defects and damage can be detected. Additional work includes attempts to simulate and predict part signatures, allowing for better estimates of baseline signatures of future parts. |

Related Publication

Non-Destructive Evaluation of Additively Manufactured Parts via Impedance-Based Monitoring