Modeling Vat Photopolymerization with Monte Carlo Ray Tracing

Project Overview

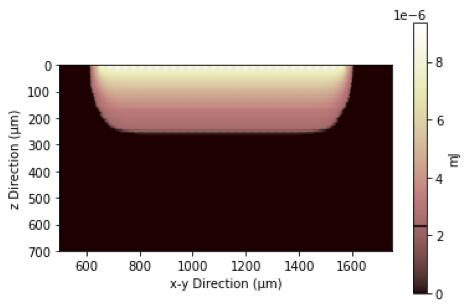

Typical vat photopolymerization resins are optically homogenous causing the UV light to go straight down in the resin. Once there are particles, such as ceramics/metal powder or polymer latexes within the resin, it becomes optically heterogenous and the incoming light is scattered. The light intensity is redistributed to the sides resulting in material curing outside of the projected location. This scattering behavior is explained through Mie Theory and is incorporated in Monte Carlo ray tracing (MCRT) simulations. MCRT casts a large number of rays, or energy bundles, these rays are subjected to being scattered elastically by the particles or absorbed by the resin medium or by particles. Once enough rays have been casted a light intensity distribution is generated and a cure profile is extracted (Image 1). These images are then compared to physically imaged cure profiles (Image 2) to test the validity of the simulation. This work is designed to assist in higher resolution printing of filled resins, resin formulation, and study the effects of particle size, refractive index difference and particle loading on the cure profile shape. Research Lead |