Topology Optimization for Multi-Axis Additive Manufacturing

Project Overview

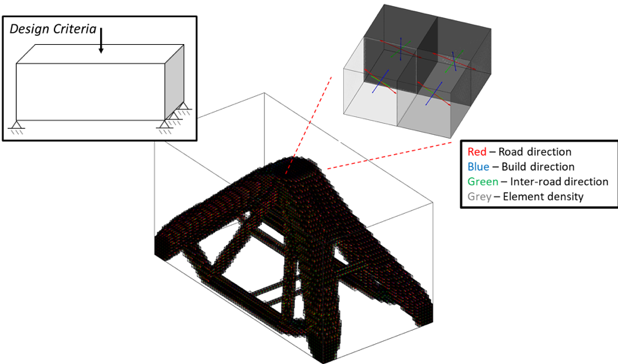

Topology optimization (TO) is a family of minimization algorithms that find the optimal material distribution relative to a set of loading conditions. These algorithms have a natural synergy with additive manufacturing (AM), as AM technologies enable the fabrication of the often organic, complex geometries resulting from TO. The typical TO problem statement does not account for process anisotropy or printing toolpath though, leading to suboptimal results. Especially in the context of multi-axis deposition, which allows material to be deposited outside of the XY-plane, designing with material anisotropy in-mind is critical for fabricating efficient structures. By incorporating 3D orientation considerations into the TO formulation, material distribution and orientation can be optimized for simultaneously. These orientations can be interpreted as desired deposition directions, allowing the TO algorithm to control both the geometry of the part as well as the toolpath used to fabricate it. |

Related Publications

J. R. Kubalak, A. L. Wicks, C. B. Williams, “Investigation of Parameter Spaces for Topology Optimization with Three-Dimensional Orientation Fields for Multi-Axis Additive Manufacturing,” Journal of Mechanical Design, pp. 1-18, 2020